Overview

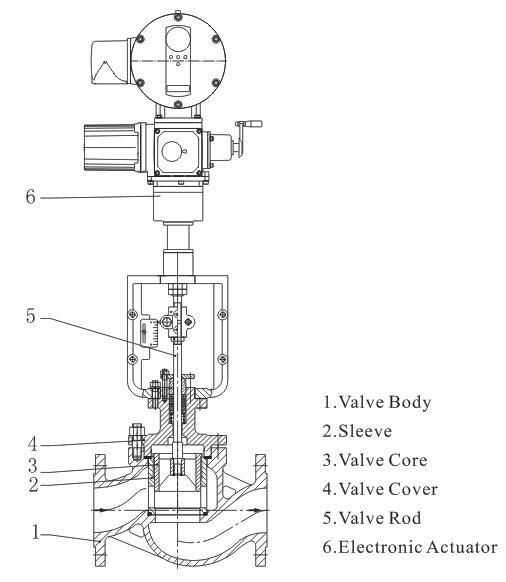

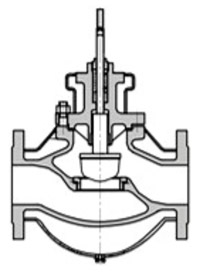

ZAZM series labyrinth type variable frequency regulating valve plus variable frequency actuator adopts top guiding structure and ball valve body. It owns such advantages as compact structure, convenient operation, high regulating accuracy, small pressure drop loss, clear flow characteristics, large guiding area and shockproof performance.

Frequency converter with built-in smart variable frequency actuator realizes reasonable use of energy. It doesn’t open frequently during control, but keeps a stable working condition and saves more than 30% energy. Meanwhile, it obviously reduces noise and prolongs service life. Without need for servo amplifier, it is directly adjusted by current signal and provides real-time feedback signal of valve position. Due to large output force, flexible action, accurate positioning and convenient maintenance, it is used to control fluid under different working conditions, adapt to harsh working conditions and reach EXDⅡBT4 explosive-proof grade.

It is widely used in industries of oil, chemical, electricity, light textile and papermaking. It is especially suitable to workplaces where allowable leakage rate is small and differential pressure before and after the valve is not very large.

Valve body

Structure category: sleeve

Valve core type: plunger type

Flow characteristic: equal percent, straight line

Structure type: symbolic type, regulation cutoff type, heat dissipation type, low temperature type, siphon seal type and jacket thermal insulation type

Nominal Pressure: 1. 6、4. 0、6. 4、10. 0Mpa

ANSⅡ150、300、600

Valve Caliber: DN20~200(3/4-8°)

Adaptive Temperature: -196~60

-20~20

-60~560

Leakage Standard: Ⅳ、Ⅴ、Ⅵ

Connection type: flange, screw thread and welding

Feature:

1. Energy-efficient, low noise;

2. With flexible closure and reliable operation accuracy, its service life is 5 times as many as that of ordinary regulating valve.

3. Valve opening and closing time is regulated quickly; valve can be opened/closed within 3 seconds.

4. Realize partition running speed and wide flow regulation range.

5. Powerful protection function and reliable operation.

6. Operation data failure is traceable and convenient for use.

Types:

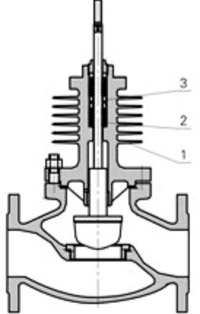

1. PO standard type: working temperature is -20~200℃; leakage grade is grade IV (Fig. 1).

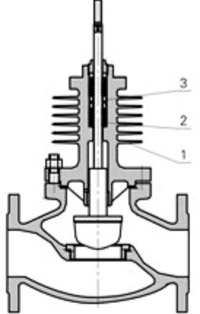

2. PG heat dissipation type adds cooling fin to valve cover. It is suitable for -60~560℃ media temperature (Fig. 2).

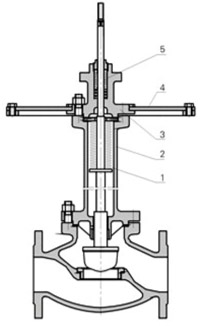

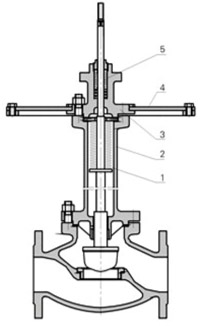

3. PV siphon seal type completely seals mobile valve rod, and eliminates fluid leakage (Fig. 3).

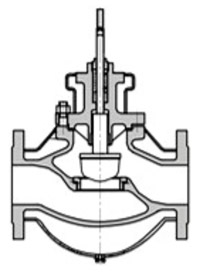

4. PD low temperature type adopts long neck valve cover and siphon seal structure. It is suitable for -196℃ cryogenic places (Fig. 4).

5. PQ regulation cutoff type soft seal structure reaches VI valve leakage grade (microbubble grade) (Fig. 5).

6. PJ jacket thermal insulation type has a thermal insulation jacket. It is used in places where cooled fluid easily crystallizes, solidifies and jams.(Fig. 6).

Common Materials of Main Parts

Valve body and valve cover: ZG230-450, ZG1Cr18Ni9, WCB, CF8, CF8M, CF3M

Valve core and valve seat: 1Cr8Ni9Ti, 204, 316, 316L

Above +PTFE

Above + bead weld of Stellite alloy

Padding: PTFE, flexible graphite

Siphon bellows: 1Cr8Ni9Ti

Gasket: stainless steel+ graphite

Valve rod: 1Cr8Ni9Ti, 304, 316, 316L, 2Cr13, 17-4PH

Note: other materials can be provided to meet special requirements. Specific materials and types are subject to order contracts.

Contact part of ΔPF regulating valve and fluid is lined with F46. Padding part is sealed with PTFE siphon seal. Therefore, it is especially suitable for automatic control of strongly corrosive media.

Δ valve core and valve seat own bead weld of Stellite alloy. It is suitable for high temperature, cryogenic and other harsh working conditions.

|

|

|

|

Fig. 2 Heat Dissipation Type

1. Cooling Fin 2. Padding 3. Isolating Ring

|

Fig. 3 Siphon Seal Type

1. Siphon Bellows 2. Lower Valve Cover (Adapter) 3. Upper Valve Cover

|

Fig. 4 Low Temperature Type

1. Siphon Bellows 2. Long Neck Valve Cover 3. Upper Valve Cover 4. Mounting Flange of Ice Chest 5. Padding

|

|

|

|

Fig.5 Soft Seal Valve Core

|

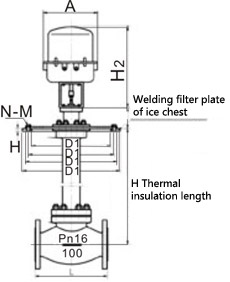

Fig.6 Jacket Thermal Insulation Type

|

|

Note: data in the table are frequently-used data of the company. They can adapt to users’ requirements.

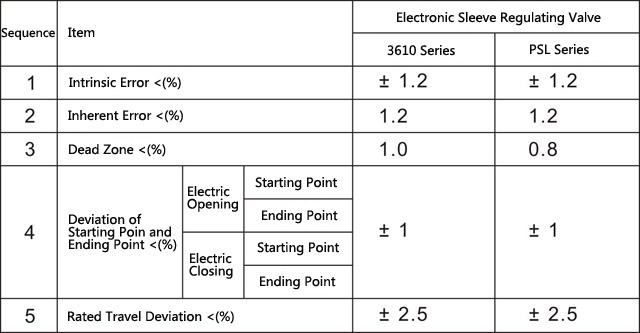

Main Performance Indexes

Note: for other parameters of the actuator, refer to “Electric Actuator Sample”.

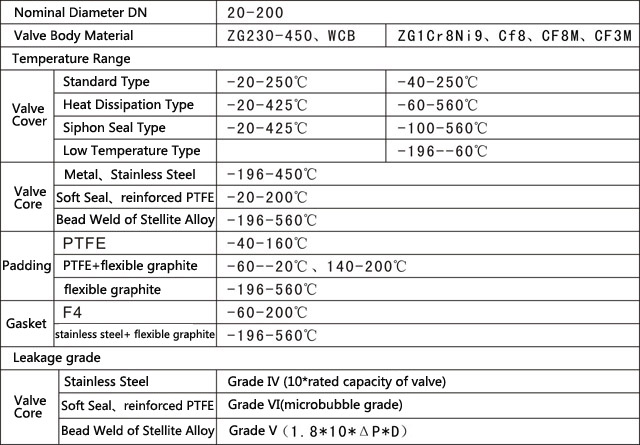

All Materials, Operating Temperature Range and Valve Seat Leakage

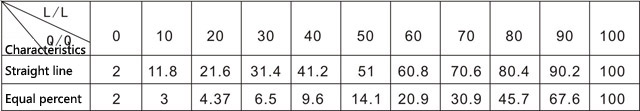

Flow Characteristic

Flow Characteristic Curve Chart

Relative flow rate value of inherent flow characteristics under relative travel R50 Unit: %

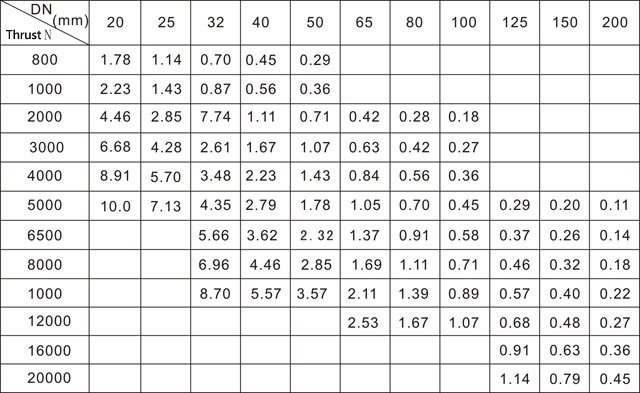

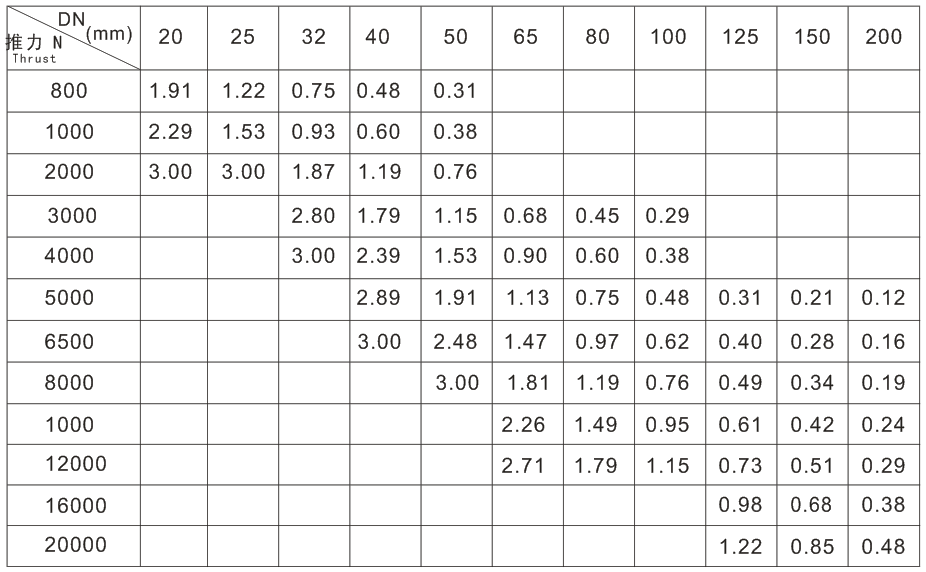

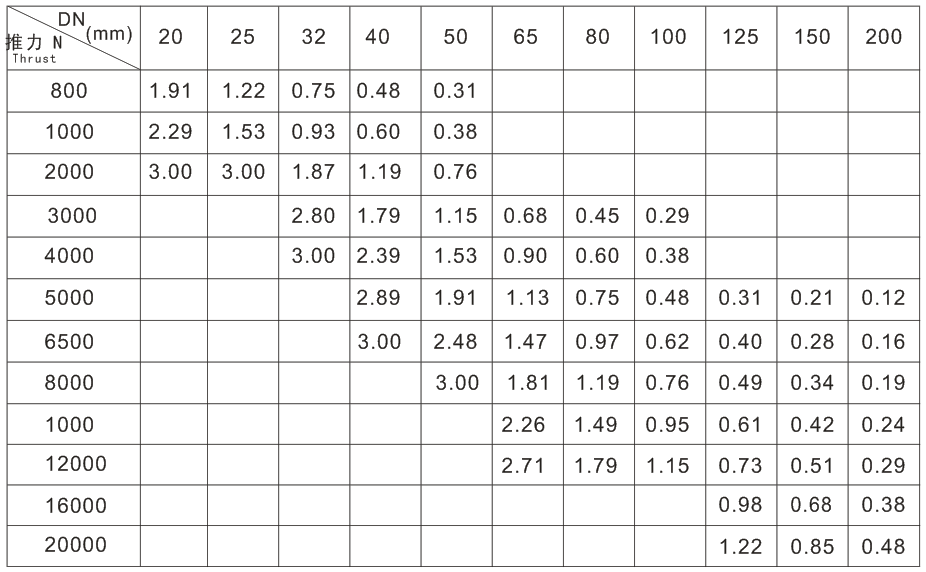

Allowable Differential Pressure

Table of Allowable Differential Pressure of Metal Seal Type

Unit: Mpa

Table of Allowable Differential Pressure of Soft Seal Type Unit: Mpa

Notes to table of allowable differential pressure:

Padding material is PTFE

The value is limited by nominal pressure and pressure-temperature chart;

Medium flow direction is contrary to the closing direction of valve core;

Re-check if siphon seal P is not equal to 0.

Leakage level of metal seal type is grade IV.

Special requirements

1. Special test

2. Use under vacuum condition

3. Complete elimination of oil and water

4. Special media (such as oxygen)

5. Copper forbidding treatment

6. Use stainless steel fittings

7. Special interface, tubing

8. Specified painting color

Connection dimension and standard

Connection type: flange, screw thread and welding (to be specified by users)

Flange standard: PN16 steel flange according to GB/T9113.1; PN40, 64 and 100 steel flange according to GB/T9113.1.

Sealing face type: PN16 is male face; PN40, 64 and 100 are male and female faces; valve body is female face.

Tip-to-face distance of flange: GB12221-89

Connection type, valve body flange and tip-to-face distance of flange can be made according to standards specified by users, such as ANSI, DIN and JIS etc.

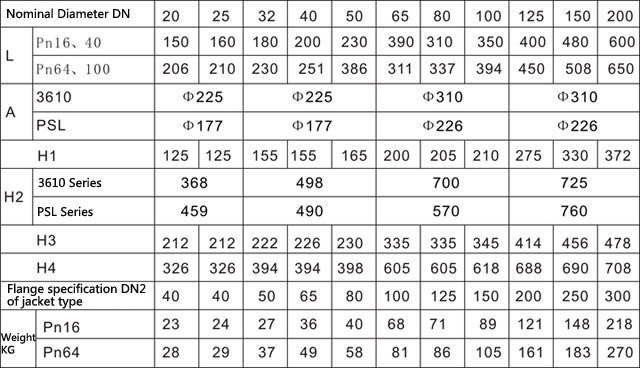

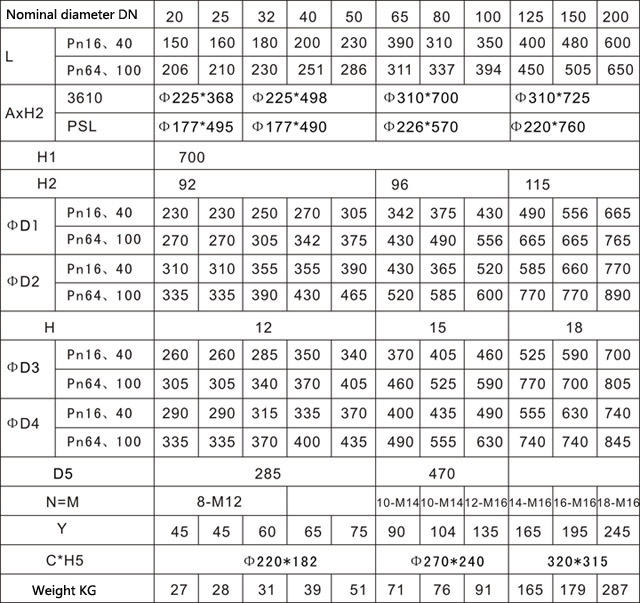

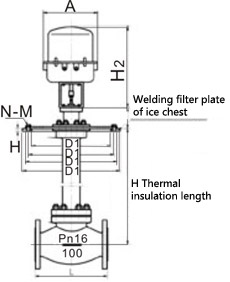

Boundary dimension and weight

Standard type, heat dissipation type, siphon seal type and boundary dimension and weight

Jacket thermal insulation type

Standard type/High-temperature heat dissipation type/Siphon seal type/Jacket thermal insulation type

Butterfly screw connection/ Socket weld connection/Butt weld connection

*Connection dimension of three types shall be inquired

Note: standard data shall be determined by specific actuator. The weight is the data of standard type without attachments such as hand wheel.

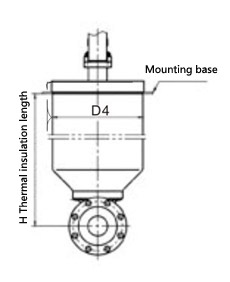

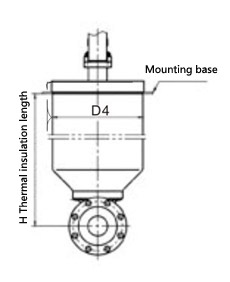

Boundary dimension and weight of PN16/40 low temperature type

|

|

|

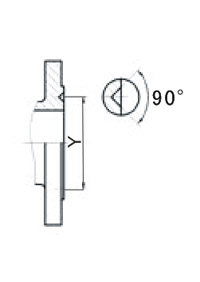

Mounting type of connecting plate

|

Mounting type of floating ring(DN20-100)

|

|

Ordering instruction

Please provide the following information clearly, in order to get more satisfying products.

1. Regulating valve name and type;

2. Nominal diameter DN(mm)

3. Nominal pressure (Mpa)

4. Inherent flow characteristic: equal percent, straight line;

5. Valve core type: metal type, soft seal type, bead weld of Stellite alloy or manufacturer’s standards

6. Action mode of the whole machine: electric opening, electric closing;

7. Connection type: flange, welding, screw thread or manufacturer’s standards;

8. Medium: name, density, temperature;

9. Technological parameter: maximum, normal and minimum flow rate;

Under the maximum, normal and minimum flow rate, valve upstream pressure P1 and downstream pressure P2;

Maximum closing differential pressure;

10. Materials of main parts: valve body, valve internals and padding etc.;

11. Electric actuator type and parameter;

12. Optional attachments of valve;

13. For jacket regulating valve, please indicate thermal coal interface type and dimension;

14. For low temperature regulating valve, please indicate thermal insulation length and connection type of ice chest;

15. Anti-explosion requirement;

16. Other special requirements.

Previous:

Is the home page

Next:

Is the end

搜派师(杭州)热电科技有限公司

搜派师(杭州)热电科技有限公司