Split Type Desuperheating and Reducing Device

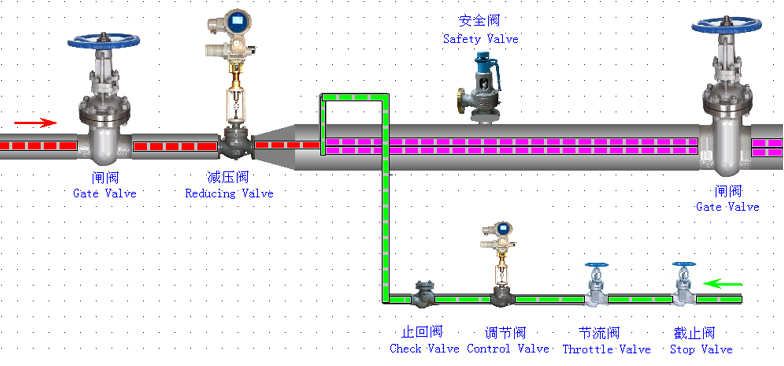

Split type variable frequency desuperheating and reducing device consists of reducing valve, restriction orifice, steam mixing pipeline (with nozzle), safety valve, feed-regulating valve, throttle valve, stop valve, check valve, desuperheating water pipe, flange and standard components. Main feature is that pressure reducing system adopts labyrinth type top guiding structure with large regulation scope and stable action, without jamming.

Desuperheating system adopts Venturi tube nozzle without transmission parts. Desuperheating water boasts good atomization effect; nozzle is featured by convenient disassembly and assembly, as well as convenient repair.

Pressure reducing system is separated from desuperheating system, which is mainly used in harsh working conditions. For example, in case of small steam flow or saturated steam (pressure is relatively low and steam flow rate is relatively low), desuperheating and reducing valve doesn’t apply; Venturi tube can be used to reduce temperature, while desuperheating water is atomized sufficiently and temperature is reduced well.

Ordering Instruction, Please provide the following information when entering into a contract:

1. Outlet steam flow Q, inlet steam pressure P1, temperature t1, outlet steam pressure P2 and temperature t2;

2. Desuperheating water supply pressure Pb、temperature tb;

3. Indicate control mode (instrument control, PLC control or DCS control);

4. Control category: electric and pneumatic;

Please provide the following information when choosing pneumatic actuator:

1) Action mode: air open type or air close type;

2) Air supply pressure;

3) Provide electrical signal of electropneumatic valve positioner;

5. Other special requirements shall be indicated after negotiations or included in another technical agreement.

Note: Due to various parameters of desuperheating and reducing device, in order to provide users with detailed and accurate conceptual drawings, designers and users shall provide detailed technological parameters. The company will design every set of device and provide conceptual drawings, in order to facilitate construction drawings and use as contract attachments.

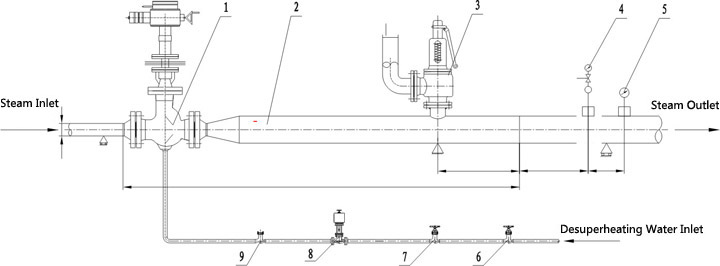

Split Type Variable Frequency Desuperheating and Reducing Device

1. Variable Frequency Reducing Device

2. Steam Mixing Pipeline

3. Spring Safety Valve

4. Pressure Gauge

5. Thermometer

6. Stop Valve

7. Throttle Valve

8. Feed-regulating Valve

9. Check Valve

User Site of Desuperheating and Reducing Device

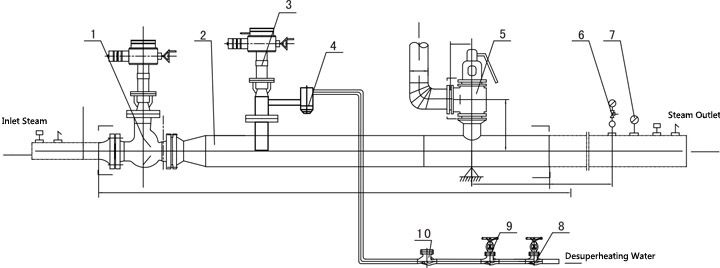

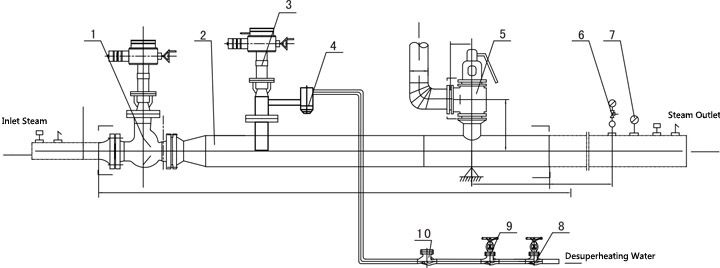

Desuperheating and reducing device with adjustable nozzle consists of reducing valve, desuperheater with adjustable nozzle, safety valve, throttle valve, stop valve, check valve, desuperheating water pipe, flange and standard components.

Main feature is that pressure reducing system adopts reducing valve structure with dual valve seats, with small unbalanced force, wide regulation range and stable action, so it isn’t locked.

Desuperheating system adopts desuperheater with adjustable nozzle; the actuator changes nozzle flow area to adjust water supply volume. Even when water supply volume changes greatly, desuperheating water always keeps good atomization effect.

Ordering Instruction:

Please provide the following information when entering into a contract:

1. Outlet steam flow Q, inlet steam pressure P1, temperature t1, outlet steam pressure P2 and temperature t2;

2. Desuperheating water supply pressure Pb、temperature tb;

3. Indicate control mode (instrument control, PLC control or DCS control);

4. Control category: electric and pneumatic;

Please provide the following information when choosing pneumatic actuator:

1) Action mode: air open type or air close type;

2) Air supply pressure;

3) Provide electrical signal of electropneumatic valve positioner;

1. Variable Frequency Reducing Device

2. Mixing Pipeline

3. Adjustable Nozzle

4. Filter

5. Spring Safety Valve

6. Pressure Gauge

7. Thermometer

8. Stop Valve

9. Throttle Valve

10. Check Valve

Previous:

Is the home page

Next:

Is the end

搜派师(杭州)热电科技有限公司

搜派师(杭州)热电科技有限公司